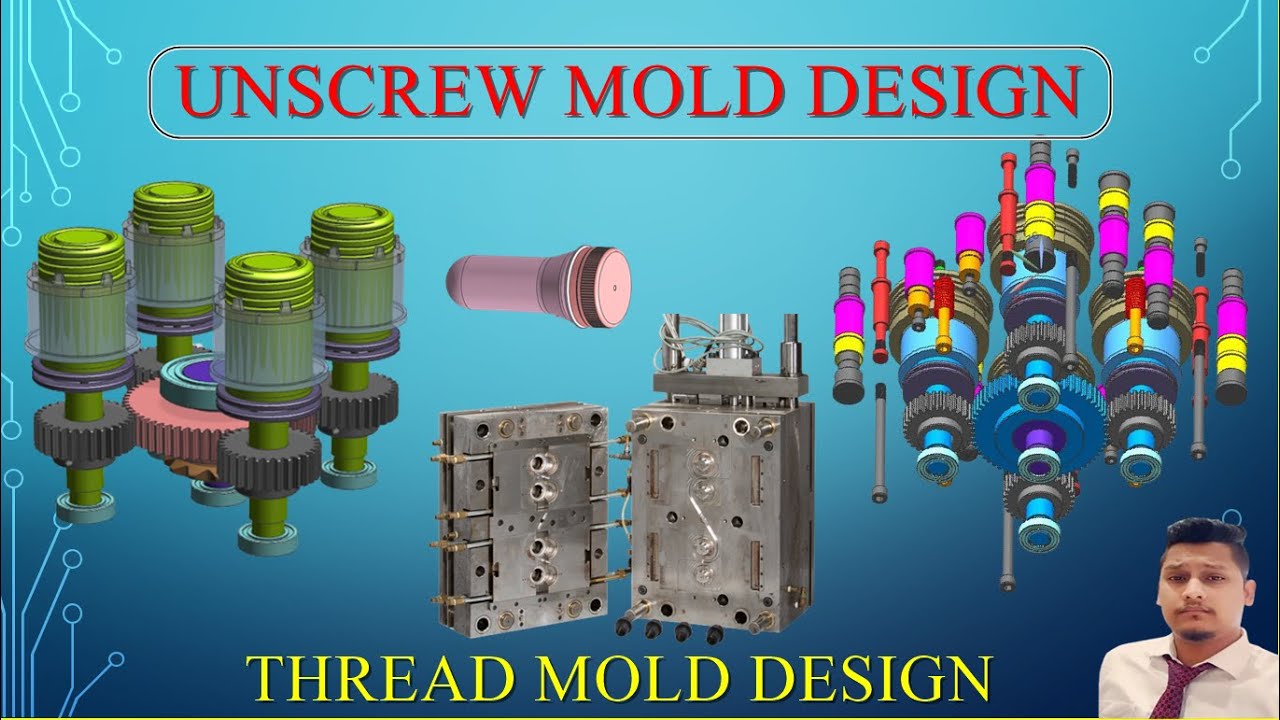

We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds. Collapsible cores or in unscrewing molds.

Elbow Injection Mold Manufacturing Solutions Upmold Injection Mold Design Mould Design Injection Moulding

Generally the complete mold design consists of designing of mold base designing of gates and runners designing of ejection mechanism and designing.

. Tion molder mold designer and mold builder. Gating locations A consequence of gating a cup shaped component from the side is the formation of weld lines. To address these needs B A Die Mold developed a new unscrewing core design that is driven electrically with servo motors.

The informa tion contained in the guide lines will maximize the molds cycle time and improve part quality with the use of copper alloys in the mold. Does the gate type match the mold design specification sheet. EW0490 Shaping Mode Injection Mould Surface Finish Process Vdi Texture Mould Cavity Single Cavity Plastic Material PE Process Combination Type Single-Process Mode Application Car Household Appliances Furniture Commodity Electronic.

Although moldmakers are always on the lookout for ways to shorten leadtimes while still maintaining quality dealing with external components and hydraulics can further complicate the mold design and build process especially. Benefits of its new Programmable Electric Rotating Core PERC system over hydraulic systems reportedly include compactness programmability fast and accurate core positioning and elimination of parts contamination with hydraulic oil. In injection molding the ejection forces decrease when the surface roughness of mold decreases.

SAM Servo Unscrewing Device Multi 16 cav. Its inventor needed a way to solve a huge problem for a customerand invented itUnscrewing molds can be a bear to operate. Will delayed ejection be needed.

Internal threads can be on collapsible cores or in unscrewing molds. The articles will begin in the May issue. UNSCREWING DEVICES FOR MOLDS TGA - BASIC UPRIGHT UNITS The Threadformer Powerful Hydraulic Motor Precision Core stopping Compact and sturdy design Unscrews 70 mm Complete single unit Threadformer installation.

The servo unscrewing devices can be constructed depending on the requirements with one 1 or two 2 gearbox levels and is based on the following parameters. Choosing unscrewing components for your molds shortens leadtimes reduces component costs and decreases cycle times. SAH Servo Unscrewing Half Market.

Plastic Injection Mold Design-Runner Gate System 31. Features The Threadformer unscrewing devices are precise sturdy and cost-efficient. 5 Product and Mold Design.

The long and short of an. Every effort should be made to locate external threads on the parting line of the mold where economics and mold reliability are. Over the decades we have developed special techniques that have established our reputation with unscrewing plastic injection mold.

Mold design has great impact on productivity and part quality directly affecting the profitability of the molding operation. D-M-E Company provides these application notes as a suggested method based upon prior applications and experience. If necessity is the mother of invention it surely applies to the PERC system.

Unscrewing Mold Design Types. Unscrewing Injection Mould Design Solutions Unscrewing Molding Manufacturer with Servo Motor Hydraulic Motor Hydrau Model NO. Also referred to as unscrewing moulds.

Unscrewing Mold Design for Protector. Unscrewing mold design with Rotary Motor driver. Design levels demanded from todays injections molds mold surface temperature control is mandatory in the molding process.

This leaves a visible trace on the surface of the. Unscrewing injection molding design of mould tool At the place that the mould tool opens prior to an unscrewing operation the piece will be kept on the shifting part of the mould tool. Thread size and length and thus maximum breakaway torque.

Specifically Adapted to Meet Your Needs. Picture D shows the. Cavity spacing and arrangement of the cavities.

These information packed Injection Mold Design Guidelines are being developed and generated by The Copper. Other mold actions include lifters wedges or slifters a new term raising members and slides sometimes referred to as. Design Drafting Machining Manufacturing Mold Maintenance Repair Contact Us Unscrewing Plastic Injection Molds Form and eject threaded plastic parts at high speeds.

0800 301 060 F. Several methods are used for unscrewing molds including hydraulic motors splines various gearing methods and for large multiple cavity molds racks and pinions are used. Mold ie by provision of unscrewing mechanisms collapsible cores etc.

Unscrewing Rack Guide Bearings Moving mold components such as unscrewing racks and cam bars which require high speed and close running fits benefit by aluminum. Hydraulic Cylinder components associated with Unscrewing mold applications. Standardized System for Molding Internal Threads Metric-rack design Off -the-shelf replacement parts Simplifies mold design Applicable to different design styles Technical and application support Rack sized to provide maximum stroke lengths Hydraulic Unscrewing Device AT P.

Are the runners sharp corners broken by 1 mm minimum and blend the transitional points of all cross-sectional size reductions. Unscrewing force rack kN unscrewing torque x number of cores radius pitch circle 15070 Nmm x 4 4019 N 402 kN 15 mm k. Specifically Adapted to Meet Your Needs.

49 6062 80933-0 Fax. Unscrewing Mold Design for Protector. To avoid thread damage such parts must be unscrewed from the mold.

External threads can be parted and molded in both mold halves. D-M-E Company assumes no liability for the construction or design of said mold or. Weld lines occur when flow fronts travelling in opposite directions meet.

Microsoft PowerPoint - Mould Design 2011bppt. In cases like this it is very important to shape the. Cavitation Size204487X204487X179375 Cavity volume24kg Part Size.

However the ejection forces increase contrary in the area of. Are runner gate location and type shown on the drawing. Single Cavity High Volume Multiple Cavity Cold Runner Hot Runner Partial Hot Runner Ejector Pin Ejection Stripper Plate Ejection Hydraulic Cylinder Activated Hydraulic Motor Activated Electric Servomotor Activated Press Opening Activated.

Can be used with. Hot Runner Molds Lifter Molds Reverse Ejection. Conventional unscrewing molds are hydraulically driven and the number and size of the.

Pdf Demolding Moment Calculation For Injected Parts With Internal Saw Thread

Automotive Radiator Grille Tooling Mold Design Download Pdf General Mould For Reference Mould Design Injection Mold Design Injection Moulding

Unscrewing Plastic Mold Design With Rotary Driving Case Upmold

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Unscrew Mold Or Threaded Gear Mould Design Or 3 Plate Injection Mold Designing In Unigraphics Nx Youtube

Collapsible Core Injection Molding Collapsible Core Mechanism Upmold Mould Design Plastic Injection Molding Molding

Unscrewing Injection Mold Design With Sliders Study Case Upmold

0 comments

Post a Comment